March 03, 2025

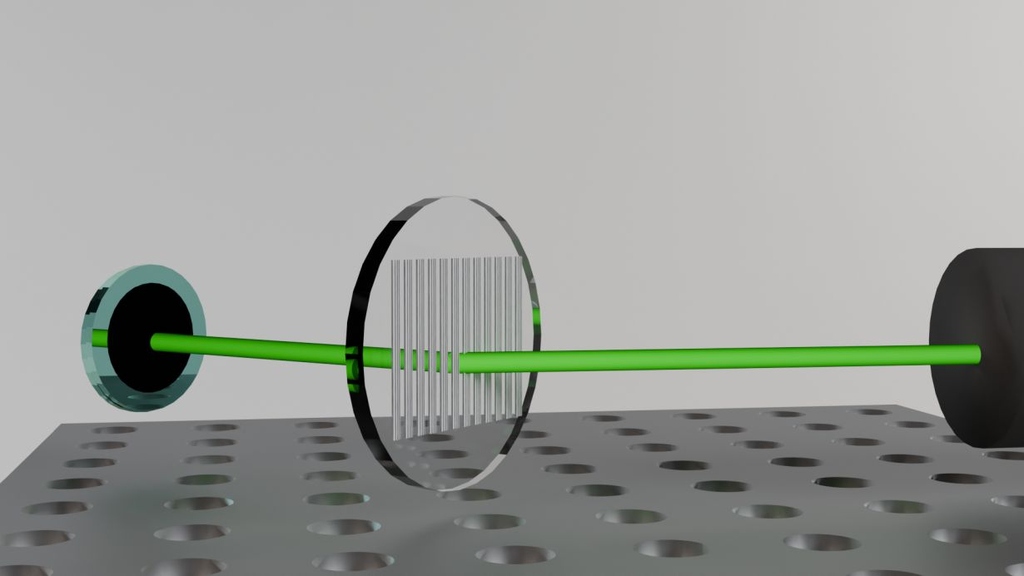

Conventional curved lenses, which direct light by refraction in glass or plastic, are often bulky and heavy, offering only limited control of light waves. Metasurfaces, in contrast, are flat and consist of an array of tiny structures known as meta-atoms. Meta-atoms influence light at a subwavelength scale and thus allow for highly precise control of the phase, amplitude, and polarization of light. “Using metasurfaces, we can influence the temporal shift, intensity, and direction of oscillation of light waves in a targeted way,” says Dr. Maryna Leonidivna Meretska, Group Leader at KIT’s Institute of Nanotechnology. “Thanks to its multiplex control capabilities, i.e. the simultaneous and targeted influencing of various parameters, a single metasurface can replace multiple optical components. Thus, the size of the optical system can be reduced without affecting its performance.” Production will also be simpler, “Metasurfaces can be manufactured using advanced lithography and etching technologies from the semiconductor industry, making scalable production is possible,” says Meretska.

Read more about optical Metasurfaces

Press Release 019/2025

February 05, 2025

Researchers at the Karlsruhe Institute of Technology (KIT) have synthesized a Bi5--ring, a molecule with five bismuth atoms, and stabilized it in a metal complex. Their discovery fills a gap in chemical knowledge and enables future applications in materials research, catalysis, and electronics. Their findings have been published in Nature Chemistry. (DOI: 10.1038/s41557-024-01713-8)

Press Release 006/2025

January 27, 2025

Prof. Dr. Stefanie Dehnen und Prof. Dr. Dr. h.c. Matthias H. Tschöp erhalten in diesem Jahr den mit jeweils 150.000 Euro dotierten Wissenschaftspreis der Weinheimer Hector Stiftung.

Stefanie Dehnen lehrt als Professorin für informationsbasiertes Materialdesign und Nanowissenschaften sowie für anorganische Chemie am Karlsruher Institut für Technologie (KIT). In ihrer Grundlagenforschung beschäftigt sie sich seit vielen Jahren mit chemischen Verbindungen. Als Expertin für innovative, anspruchsvolle und zugleich nachhaltige chemische Synthesen kombiniert sie aus den bekannten Elementen bisher unbekannte Verbindungen und Stoffe, die neue Eigenschaften haben. Diese sogenannten Clusterverbindungen gelten als das entscheidende Bindeglied zwischen einzelnen Atomen und nicht atomar definierten Nanopartikeln. Ihre ungewöhnlichen Eigenschaften und Reaktivitäten machen Clusterverbindungen zum Ausgangspunkt für innovative Funktionsmaterialien.

Pressemitteilung idw - Informationsdienst Wissenschaft

December 12, 2024

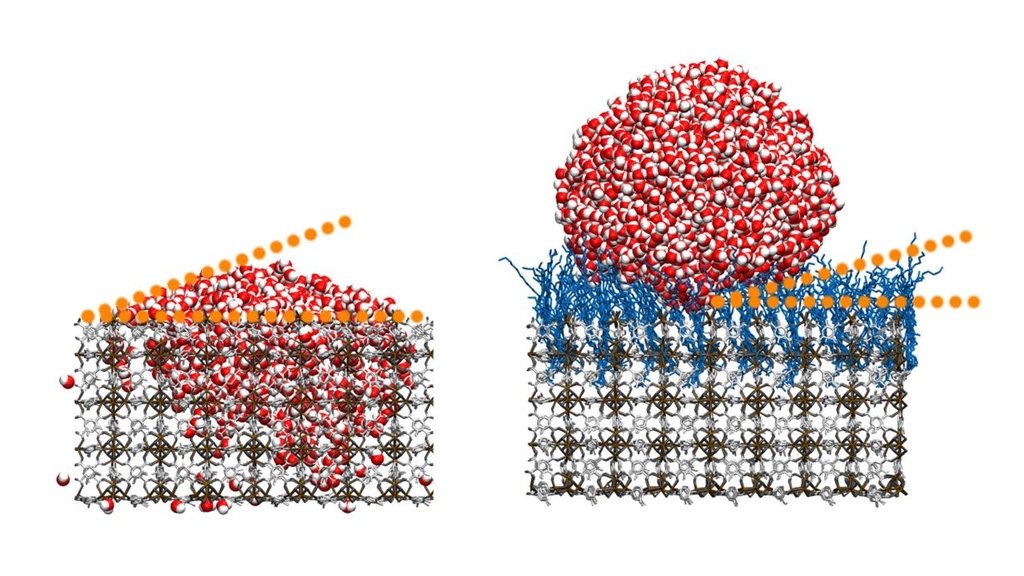

Scientists from Karlsruhe Institute of Technology (KIT) and the Indian Institute of Technology Guwahati (IITG) have developed a surface material that repels water droplets almost completely. Using an entirely innovative process, they changed metal-organic frameworks (MOFs) – artificially designed materials with novel properties – by grafting hydrocarbon chains. The resulting superhydrophobic (extremely water-repellent) properties are interesting for use as self-cleaning surfaces that need to be robust against environmental influences, such as on automobiles or in architecture. The study was published in the Materials Horizons journal. (DOI: 10.1039/D4MH00899E)

Press Release 105/2024

On November 5, 2024, around 170 participants – both on-site and online – gathered for the fourth MSE-Day at the Forschungszentrum Jülich to discuss current developments and progress in the Helmholtz program “Materials Systems Engineering” (MSE). The event’s multifaceted agenda, featuring presentations, poster sessions, and in-depth discussions, provided exciting insights into the interdisciplinary research approaches and the ongoing development of the program.

The Helmholtz program “Materials Systems Engineering” (MSE), supported by KIT, Hereon, and FZJ, combines information-based synthesis and characterization methods with interdisciplinary research expertise to develop new materials and material systems that enable innovative and sustainable solutions.

The MSE-Day has established itself as a central platform for presenting current research results and fostering exchange and collaboration among researchers of all ages and disciplines.

Read more: Helmholtz Blogs - Compass of the Research Field Information

November 11, 2024

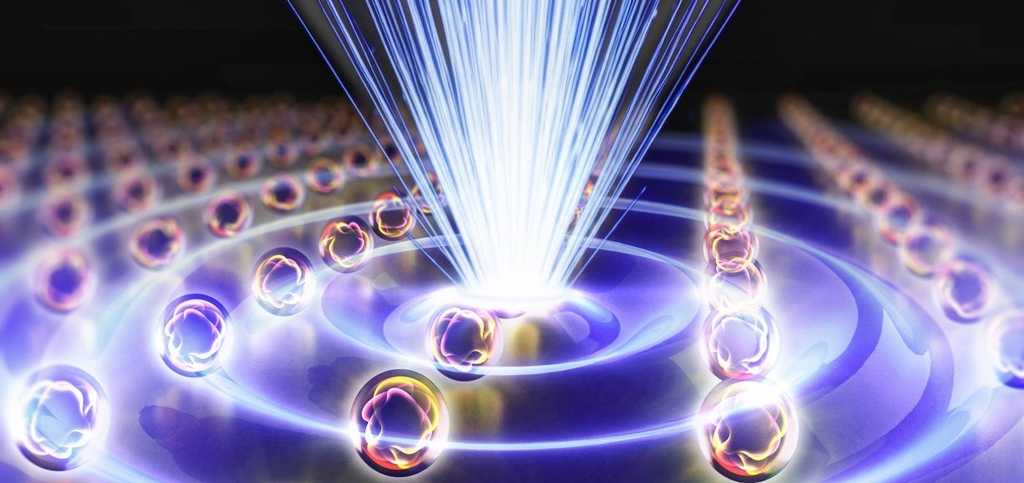

Photonic space-time crystals are materials that could increase the performance and efficiency of wireless communication or laser technologies. They feature a periodic arrangement of special materials in three dimensions as well as in time, which enables precise control of the properties of light. Working with partners from Aalto University, the University of Eastern Finland and Harbin Engineering University in China, scientists from the Karlsruhe Institute of Technology (KIT) have shown how such four-dimensional materials can be used in practical applications. They published their results in Nature Photonics. (DOI: 10.1038/s41566-024-01563-3).

Press Release 090/2024

November 5, 2024

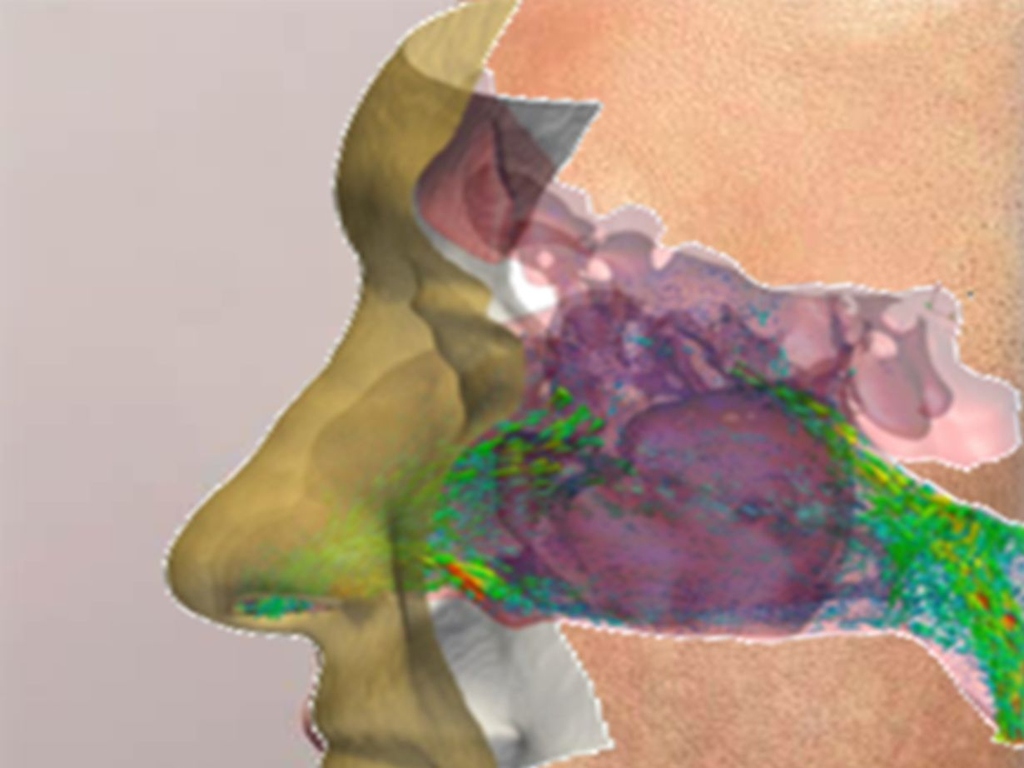

In future medicine, personalized computer models, so-called Virtual Human Twins, could help in the planning of individual therapies. Today already, human organs can be simulated on chips or in petri dishes: Scientists are developing computer-aided methods and in-vitro technologies that are intended to reduce or even replace animal testing. The new 3ROCKIT 3R Center at KIT (Karlsruhe Institute of Technology) is a driving force behind this endeavor. As of January 01, 2025, Baden-Württemberg will add it to the statewide 3R network, funding it with EUR 100,000 per annum for three years.

Press Release 088/2024

November 5, 2024

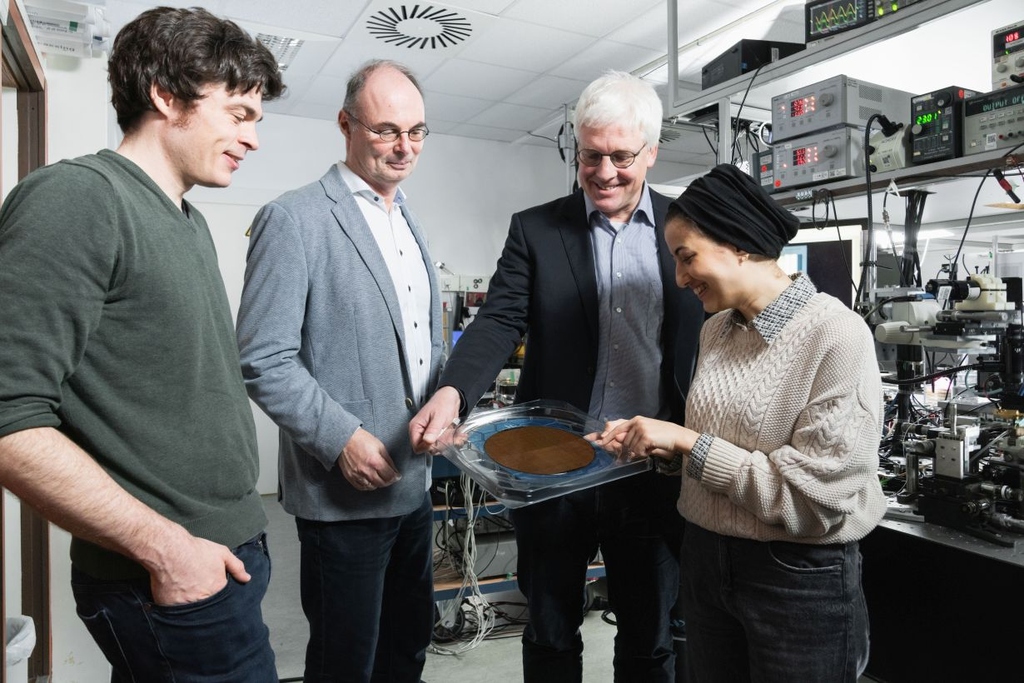

The European Research Council (ERC) is funding the ATHENS research project headed by professors Christian Koos and Stefan Bräse of the Karlsruhe Institute of Technology (KIT) with a Synergy Grant. The project’s objective is to improve the performance and energy efficiency of optical communications systems. Given growing demand for the transmission of large volumes of data by artificial intelligence (AI) applications, such improvements are especially relevant. The ERC is funding ATHENS for six years with EUR 14 million. One location where work on the project will be performed is the Karlsruhe Center for Optics and Photonics (KCOP), which is set to open in 2025.

Press Release 087/2024

November 04, 2024

3,1 Millionen Euro für EU-Projekt NANO-S-MART: KIT forscht für besseres Produkt und weniger Verbrauch in der Stahlindustrie

Stahl gilt als „Musterschüler“ in der Recyclingindustrie und wird oft als vollständig wiederverwertbar angepriesen. Doch die Realität sieht anders aus: Jährlich exportiert Europa Stahlschrott in der Größenordnung des deutschen Stahlverbrauchs in Schwellenländer. „Die erforderlichen Materialqualitäten in Europa werden nicht mehr erreicht, weil sich durch den Kreislaufprozess Verunreinigungen im Stahl konzentrieren“, sagt Professor Christoph Kirchlechner vom Institut für Angewandte Materialien des KIT. „Unser Projekt will das Verständnis für den Umgang mit schädlichen Elementen im Recyclingprozess vertiefen und den Weg zu nachhaltigeren Materialkreisläufen ebnen.“

Read more

October 24, 2024

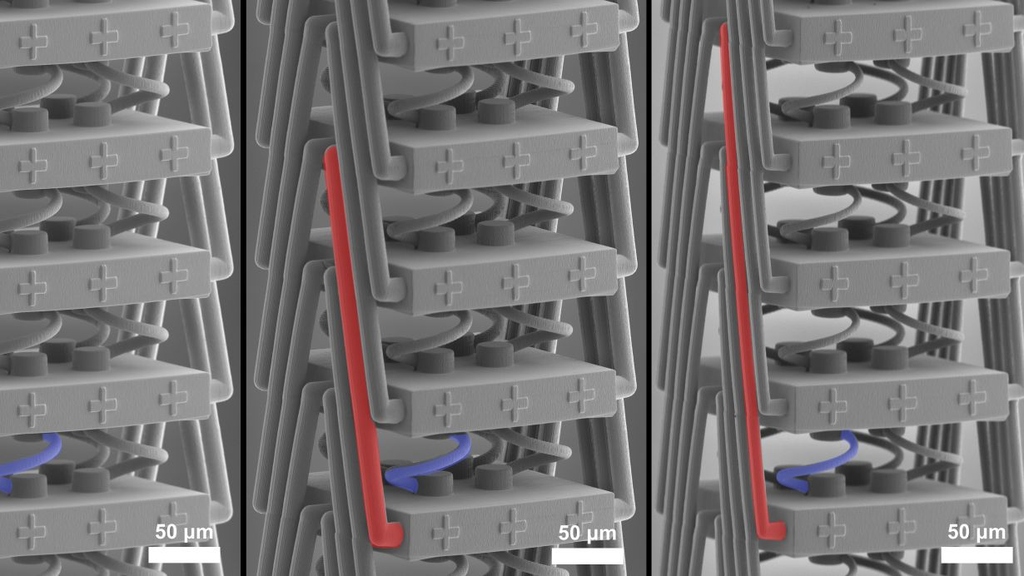

Metamaterials are artificial materials that do not occur in nature. Their components function like atoms in conventional materials but have special optical, electrical and magnetic properties. Interaction between the components is crucial to a metamaterial’s functionality. Previously a component could usually interact only with its immediate neighbors. Researchers at the Karlsruhe Institute of Technology (KIT) have developed a mechanical metamaterial with which these interactions can also be triggered at greater distances within the material. Potential uses of the material include measuring forces and structural monitoring. The findings have been published in Nature Communications. (DOI: 10.1038/s41467-024-52956-5).

Press Release 084/2024

September 3, 2024

Researchers of Karlsruhe Institute of Technology (KIT) and Voxalytic GmbH developed a new method that allows, for the first time, to elucidate the chiral structure of molecules – the exact spatial arrangement of the atoms – by nuclear magnetic resonance (NMR) spectroscopy. This important step in the development of new drugs used to be a time-consuming process until now. The new method could now become a standard tool for the chemical and pharmaceutical industries. The results were published in the Advanced Materials journal. (DOI: 10.1002/adma.202408547).

Press Release 066/2024